DRILLING

Oil, Gas, & Water

Drilling/Water Well

With over 40 years of experience in oil, gas, and water well drilling repair and rebuilding services, our machinists, mechanics, and welders offer dependable and quality work in the field or in the shop to get you back up and running.

Field Services

We offer field mechanics that will travel to the entire continental United States, servicing mainly Texas and Oklahoma, Kansas, New Mexico, Colorado and Nebraska. Our field mechanics are experienced in rig rebuilds in the field and can also transport equipment back to the shop for rebuild.

We offer complete disassembly and rebuild to get you back up and running in a timely manner. Our experience includes drawworks, mud pumps, crown assemblies, hook and blocks, tongs, shafts, rotary tables, triplex pumps, duplex pumps, gearboxes, water boxes, clutches, Twin Disc clutches, rotary clutches, top drives, and more.

We have experienced field welders available 24/7/365 that travel throughout Texas and Oklahoma providing strong and accurate cutting and welding to repair your equipment to proper working condition. Our field welders repair and modify rigs to bring them to proper safety compliance. We cut and repair strap and casing. We fix cattle guards and repair fences. We build and repair flow lines. We repair mud pits and tank batteries. We rework heat exchangers. We make fabrications. We repair handrails and build staircases. We build braces and brackets. We build hinges. We build conductor pipes. We build and install risers for water tanks. We install bell nipples. We weld eyes on diesel tanks. We install buoy lines. We weld on wellheads. We vee-out and weld cracks. We repair suction lines. We build conductors. We repair mud troughs. We build skids, gates, and shelves. We build fire extinguisher boxes and brackets. We can help with all your welding needs.

Off Loading Generator

Fleet of Heavy Hauling Trucks

Tandem Hauling an Oil Derrick

Payton Portable Field Office

Off Loading Drawworks

Off Loading Drawworks

Shop Services

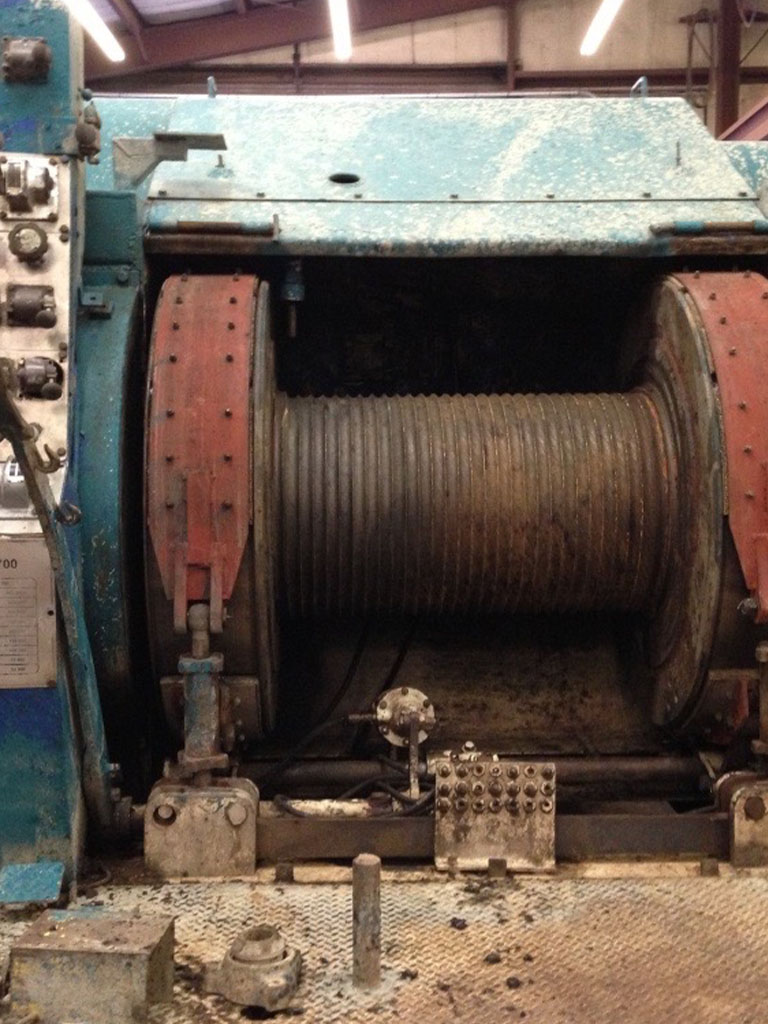

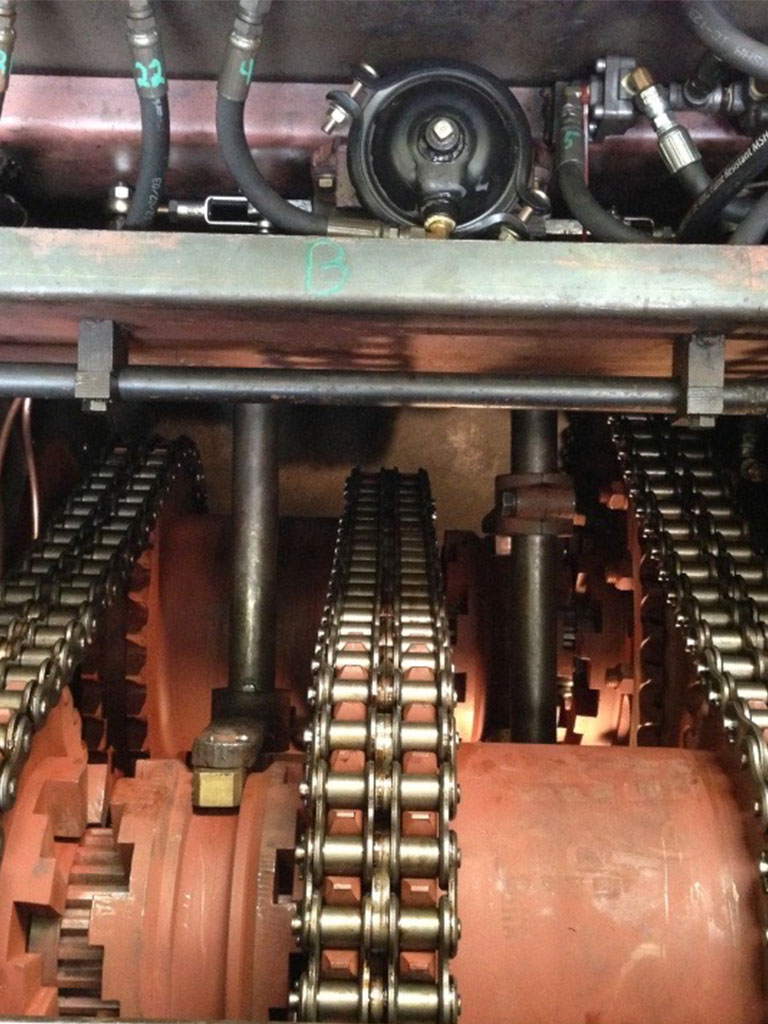

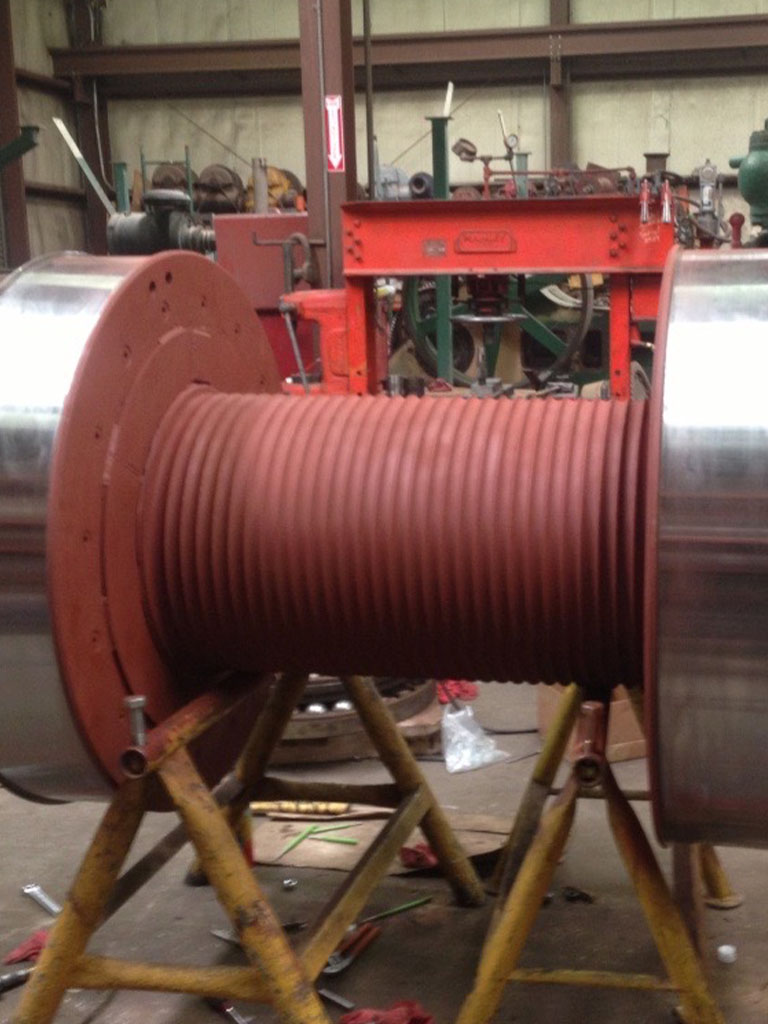

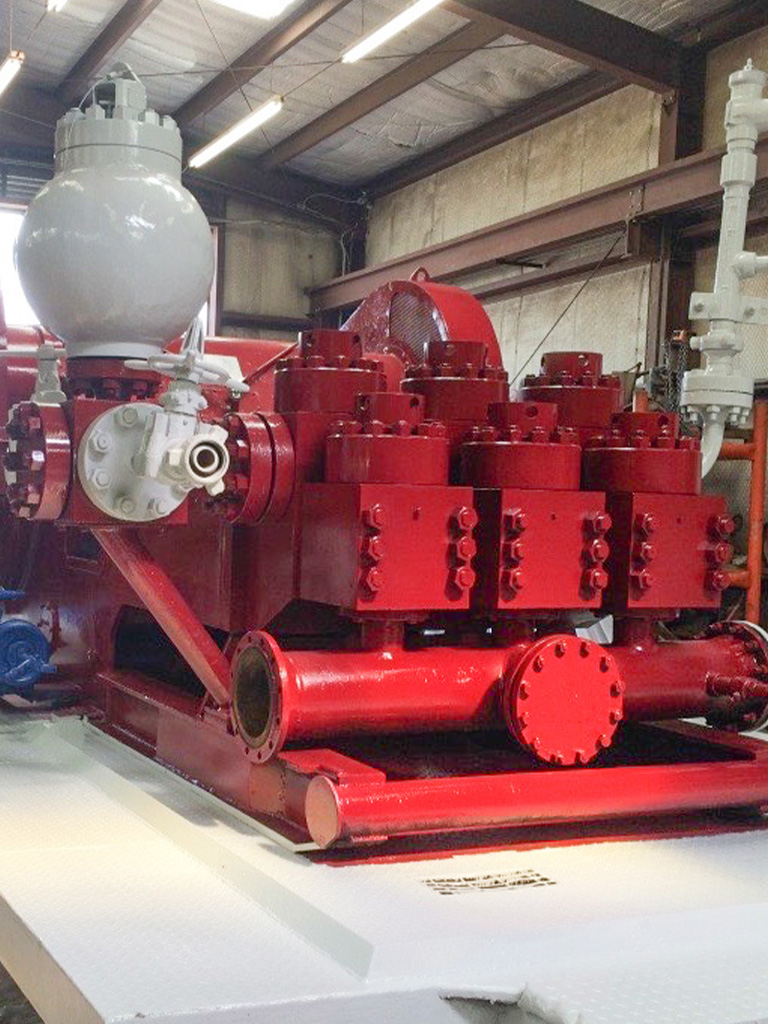

We completely rebuild and rework drawworks, specializing in U-15 drawworks, U-34 drawworks, Gardner Denver GD800 drawworks, 3000E drawworks, U914 drawworks, National 80B drawworks, National 110UE National drawworks, C1 Emsco drawworks, National 620 drawworks, just to name a few. We rebuild crown clusters. We rework crown assemblies and Crown-O-Matics. We rebuild hook and blocks back to API standards. We rework mud pumps (Gardner Denver, Oilwell, Emsoco, and National) including triplex pumps, duplex pumps, PZ10 mud pumps, PZ9 mud pumps, 10-P-130 mud pumps, 9-P-130 mud pumps, HH1600 mud pumps. We rework 10-P-130 valves and plugs. We rebuild PZ11 modules. We rework all sizes of Twin Disc and Wichita clutches. We bore clutches and clutch hubs. We build and bore sprockets. We rework rotary clutches. We completely rebuild and repair crankshafts, con-rods, essectric rods, crossheads, wrist pins, bull gears and pinion gears. We rebuild catheads and cat shafts. We rebuild and line-up traction motors. We completely rebuild main drums and sand line drums. We rework ware plates, kick plates, and Lebus grooving. We rework jaw clutches on drums. We build shafts, compound shafts, input and output shafts, jackshafts, Agitator shafts, and cam shafts. We rebuild gearboxes. We build and repair guards. We rebuild hydromatic brakes. We rebuild rotary tables. We rebuild waterboxes. We rework water spears for high clutches. We furnish Kelly Drive Rollers. We rework 90 degree gearboxes and gear reducers. We build air tanks. We straighten tie rods. We rework swivels. We furnish and rebuild makeup catheads and breakout catheads. We rebuild cylinders. We build and weld derrick pad eyes. We rework drilling line spools. We furnish brake rims. We rework brake assemblies. We furnish brake shoes. We rebuild compound motors. We rework hydraulic ram skid. We rebuild brake components. We rework bit feed components. We rework power tongs and breakout tongs. We change Idler bearings. We rework torque converters. We disassemble and rework Blow-Out Preventers (BOPs). We build test plugs for BOP. We rework ring grooves. We repair ram blocks. We rework fast line bearings. We furnish change out low and high clutches. We rebuild top drives, hydraulic top drives, and mount top drive. We rebuild tail pump drives. We rework piston grip quick changes. We pull and rework fluid ends. We install pony rod seals. We install pulsation dampners. We rework pump manifolds and splitters.

Rebuilt rotary table and swivel

Main drum on drawworks

Chains on a drawworks

Rebuilt drawworks main drum

Hook

Rebuilt mud pump

Mud pump ready for shipping

Pump Jacks

We have specially equipped trucks and field mechanics that can pole up and set off pumping units onsite, allowing for complete rebuilds or partial equipment rebuilds. We can move units to second locations and transfer equipment between unit locations. We rework saddle bearings, tail bearings, and wrist pins for Cabot, Lufkin, Parkersburg, American, Bethlehem, National and Emsco units. We rework complete units. We rework Sampson posts, gearboxes, walking beams, and equalizer beams. We rethread bailer bottoms. We rework tubing spears and grapples. We build fishing tools. We rework sand pumps, protectors for sand pumps, stingers, and spears for sand pumps. We rework Pitman arms and bushings. We rework power tongs and hydraulic tongs. We rework chisel bottoms. We build and rebuild drag rings. We rework water systems and brake systems. We rework compressors. We rework elevators, upset elevators, and tubing elevators.

Loading pump jacks for delivery

Pump jack

Payton maintenance on a pump jack

Machining &

Fishing Tools

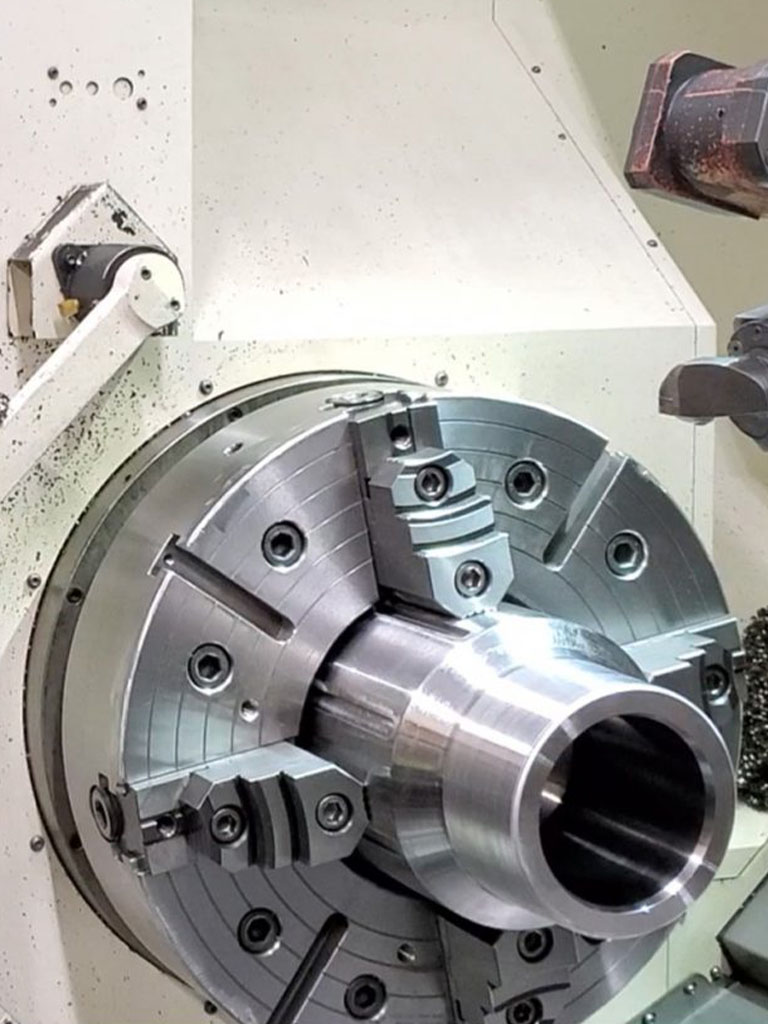

We have CNC lathes and manual hollow spindle machines and operators with expertise to cut, cut off, and recut threads on drill collars and drill pipe to certain specifications. Our hollow spindles lathes have up to 12″ front and rear chucks with beds of 28″ x 144″. We do not run CNC manufacturing, but we manually cut pins and relief grooves as well as cut boxes and bore backs. We kemplate ends. We cut spiral drill collars. We clean, gauge and face joints. We straighten drill collars and Kellys. We rework Kelly hoses. We build and rework subs, TIW valve subs, handling subs, changeover subs, swivel subs, and Kelly saver subs. We bore for float and cut float seat. We turn the OD and drill the ID on drill collars, drill pipe, and subs. We rework and bevel casing. We cut lip guides and fishnecks. We face joints. We cut cable tool joints. We build swedges. We rework washpipe. We cut Left Hand joints. We cut Hydrill pins and Hydrill boxes, Insert pins and Insert boxes, PH6 pins and PH6 boxes and DI22 joints. We chase threads in overshot bowls. We cut bit jars. We thread API casing. We rework sand pumps. We build up joints with brass.

We have manual machines and operators with immense experience. We can to build and rebuild mills and fishing tools to certain specifications. We are able to build and rework concave mills, string mills, taper mills, flat bottom mills, pilot mills, Kutrite mills, round nose mills, bull nose mills, clutch mills. Build and rework Kutrite shoes, mule shoes, screw-in shoes, insert shoes and Hydrill shoes. Build lift nubbins. Build pin and box protectors. Build junk baskets. Build barrels. Build ball guns.

Fishing Tools

Drill pipe

Rebuilt drill collar

Precision machining of drill collar

Have one of our experts contact you as soon as possible.

All Rights Reserved © 2020

Site developed by Itech Design