Our mechanics, machinists, millwrights, welders, and technicians have over 40 years experience serving industrial plants including carbon black, fertilizer, methane, natural gas, ethanol, asphalt, food-processing plants, wind energy, and more. Our crews help to build and rebuild parts and equipment in accordance with API guidelines and industry standards. We travel to plant locations to help with emergency unplanned shutdowns, turn-arounds, repairs, overhauls, and even preventative maintenance. Our field services include inspecting, disassembling, trouble shooting, repairing and reworking, assembling, installing, maintenance and servicing, pressure washing, sandblasting, “boltup” crews, machining, and welding. Our field welders are experienced in general as well as specialty welding on a variety of materials including, but not limited to, aluminum, stainless steel, cold-roll material, 4140, cast iron, and brass.

We also offer emergency services of on-call crews with skilled millwrights, mechanics, and welders to work around the clock to get you back up and running as quickly as needed.

When time and budget doesn’t allow for equipment to be removed and brought into our shop, we take pride in our ability to bring field machining capabilities to your location.

Our crews have experience with and knowledge of various parts and equipment throughout the plant industry including, (but not limited to), steam turbines, centrifugal compressors, reciprocating compressors, screw compressors, GE compressors, duplex pumps, triplex pumps, oil pumps, water pumps, centrifugal pumps, displacement pumps, gearboxes, fans, fan bases and pedestals, fan hubs, fan housing, paddle fans, submarine fans, impellers, Hoffman blowers, Roots blowers, offgas blowers, RTO blowers, repressure blowers, air blowers, heat slingers, packing glands, sight glasses, turbines, steam turbines, Murray turbines, Elliott turbines, Corpus turbines, generators, motors, hydraulic systems, pneumatic systems, roll crushers, Dela valves, butterfly valves, knife valves, Starr valves, Vortex damper valves, relief valves, suction valves, check valves, rivet valves, packing pushers, mixers and mixer shells, mixer elements, foundation repair, duct work repair, equipment structure repair, and so much more.

Payton Machine & Supply is dedicated to solving your problems with experienced and dependable personnel. Whether you need a new design, a fabrication, a complete rebuild/overhaul, or a repair, Payton Machine has the capability and experience needed to tackle your requests in-house. We have a wide range of capabilities using our CNC lathes, manual lathes, CNC mills, manual mills, large capacity horizontal and vertical presses, vertical mills, key broaching machines, large bore hollow spindles, radial drill press, and vertical drill presses capable of handling both small and large parts. We also are proud to offer the largest in-shop dynamic balancing machine in the Texas panhandle.

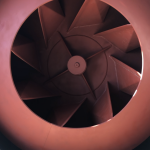

We build and rebuild blowers and fans of all sizes and applications including overhung blowers, center hung blowers, paddle fans, enclosed blowers, re-pressurizing bowers, thrust blowers, cooling tower fans, Buffalo blowers, Roots blowers, steam turbines, and offgas blowers. We build and rebuild packing glands and mechanical seals. We straighten and rebuild augers. We machine auger pins. We rework sight glasses and build extensions. We rework packing pushers. We furnish and rework butterfly valves, Starr valves, air lock valves, blade valves, rotary valves, gate valves, knife valves, pressure relief valves, water valves and feed valves. We build valve control stems. We build new and rebuild burners. We build and rebuild oil spray tips and nozzles. We rebuild and pour Babbitt bearings. We rework mixer shells, mixer shafts, and mixer elements. We build mechanical seal sleeves and stationary rings. We rework oil pumps, water pumps, dryers, dryer seals, gearboxes. We build specialty sleeves for gearboxes and mixers. We rework conveyor belts. We rework and build compressors. We rework electric motors. We build new and rebuild mikro reels. We furnish pinion gears, liner assemblies, and pumps. We rework and build new shafts, elevator shafts, cam shafts, tail shafts, drive shafts, pump shafts, fan shafts, impeller shafts, and jackshafts. We build plates for motor bases. We rework drive couplings. We build seal rings. We rebuild and build new trunion rollers. We build offset keys and taper plugs. We rework thrust rollers. We build Orifice plates. We pull motor hubs. We build grudging pins and air cylinders. We rebuild actuator arms. We rebuild gearboxes, dryer gearboxes, Marley gearboxes, Stober gearboxes, and Foote Jones gearboxes. We rebuild steam turbines. We rework hydraulic motors and electric motors. We line up traction motors. We perform laser alignment and dial indicator alignment of motors, turbines, generators, and gearboxes from single to multi-stage trains. We rework heat exchangers. We build dowel pins. We furnish, build, and machine shims. We build nylatron spools. We rebuild and repair pneumatic and hydraulic cylinders. We build and rework stack cylinders. We build Micarta extensions. We rework chrome cylinders. We build drive lines and band wheels. We rebuild roll crushers for concrete plants.

We have diesel and heavy equipment mechanics that can help get your construction equipment back up and running.We rework backhoes, excavators, front end loaders, bulldozers, trash trucks, and dump trucks. We rework hydraulic cylinders, pins, and axles. We rebuild compressors and straighten hydraulic booms. We rework buckets. We build oilfield beds for trucks and rebuild rolling tailboards for trailers.

We are proud to offer comprehensive industrial solutions including data collection, vibration analysis, motion amplification, dynamic balancing, field dynamic balancing, and field alignment. We have personnel trained and certified to help you perform preventative maintenance and trouble shooting in the field. We have personnel with ISO Category II Vibration Analyst Training Certification, RDI Iris M Motion Application Training Certification, Level II-Balancing Technician certification in Fundamentals of Balancing and in Balancing Theory and Applications.

Our alignment equipment technology is at the front of the industry offering horizontal machine, vertical machine, and machine train alignment.

We have a HM5B Schenck dynamic balancing machine with the Cab 820 measuring unit operated by a certified Level II – Balancing Technician. Our machine is capable of swinging up to 106” diameter parts with weight up to 15,000 pounds. We provide certification forms with every job. Our machine is capable of balancing all grades of rotors, spindles, multi-stage turbine rotors, crankshafts, ventilators, pump impellers, drive assembly components, gear wheels, and so much more. We offer top of the line equipment run by a trained and certified ISO Level II balancing technician, for machine condition monitoring, plant condition monitoring, and operational balancing in the field. Our equipment offers fast, reliable route-based data collection and offers technology that reduces exposure to safety hazards during data collection.

We will help you create a maintenance plan to routinely monitor your equipment with vibration analysis, motion applications imaging, and/or alignment checks based on your businesses goals and your equipment needs. Consistent monitoring provides less likelihood of failure, decreased downtime expense, and potentially increased profit.